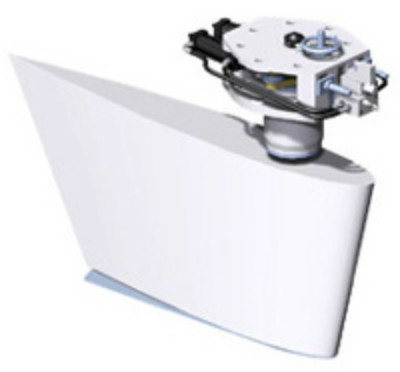

stabelizer model 720

Call 954-577-2850 or Send Enquiry for Pricing

For vessels from 150-200ft (45-61m)

The NAIAD Model 720 Fin Actuator Assembly is designed for efficiency, power and rugged reliability. It is supplied completely factory tested under pressure, assembled and ready for installation including all required hardware and fittings. Unlike other systems, no disassembly is required for installation. NAIAD Fin Actuator Assemblies are recognized the world over as the industry standard for excellence.

Description

| Standard Fin Sizes: | 45 sq.ft. (4.18 sq.m), 53.8 sq.ft. (5.00 sq.m), 64.6 sq.ft. (6.00 sq.m), 75.3 sq.ft. (7.00 sq.m) |

| Fin Attachment: | Precision machined oversized self-locking taper. A precision machined spiral groove along the length of the tapered surface allows for easy, hydraulically-assisted fin installation. |

| Main Shaft: | 8.0 in. dia. (203.2 mm) heat-treated stainless steel. |

| Fin Actuator Housing Material: | High strength ductile iron; 2.5 times stronger per square inch than aluminum. |

| Upper AND Lower Bearing: | Heavy-duty tapered roller bearings by a leading manufacturer such as Timken (TM). |

| Lower Seal: | Three double-lip seals for maximum seawater protection. Easily accessible in a 316 stainless steel retainer. |

| Upper Seal: | Double-lip, spring-loaded seal for grease retention. The double-lip design also provides protection of the fin actuator against external contaminants. |

| Lubrication: | Pre-packed with high quality Lubriplate (TM) water-resistant grease for lifetime maintenance-free service. |

| Hydraulic Connections: | SAE O-ring ports and (JIC) 37° flare fittings (not pipe fittings) for leak-free service. |

| Hydraulic Cylinder: | Custom engineered for NAIAD stabilizer applications in collaboration with a world leading cylinder manufacturer. Double acting twin cylinder arrangement. Steel body construction with high strength tie rods for heavy-duty service. Self-regulating shock reducing cushions. |

| Cylinder Mounting: | Head Trunnion mount allows most compact Fin Actuator design. Trunnion freely pivots in dual high capacity roller bearing assembly. |

| Maximum Working Pressure: | |

| Cylinder Bore Diameter: | 4.00 in. (101.6 mm) |

| Rod Diameter: | 2.50 in. (63.5 mm) |

| Rod End: | High strength hardened steel rod end with sealed heavy duty precision double row spherical roller bearings. |

| Rod End Pins: | Through-hardened, ground and passivated stainless steel. |

| Torque Arm: | Cast and heat-treated high strength ductile iron, cadmium plated for corrosion resistance. Honed bore for precise Rod End Pin fit. |

| Shaft-Torque Arm Connection: | Oversized clamped precision spline for maximum torque capability. |

| Overall Weight: | |

| Overall Dimensions: | See dimensional drawing. |

| Fit & Finish Throughout: | High ‘yacht’ quality, painted, plated and polished. |